For most artifical accelerated tests in laboratory, getting a consistent testing results with outdoor is the most important purpose. Prior to cyclic corrosion testing, conventional salt spray (a continuous salt spray at 35˚C), was the most popular way to simulate corrosion in a lab. Because conventional salt spray methods failed to simulate the natural wet/dry cycles of the outdoors, test results frequently provided poor correlation to outdoors. In order to better simulate the complex and changeable external natural environment, cyclic corrosion test has gradually been considered as an important and effective method for the life assessment of industrial products.

The Cyclic Corrosion Test Cabinets is also called CCT&CRH Cabinets. Some industrial products need to be exposed to repeated cyclic salt spray, dry and static environment with high humidity and low humidity. These tests were initially switched between several test chambers manually. The multi-functional Cyclic Corrosion Test Cabinets solves this problem well, and realizes the automatic test of these cycles in a chamber.

In a typical cyclic corrosion cabinets, all specimens are exposed to a series of different environments in a repetitive cycle that simulates the outdoors. Simple cycles, such as Prohesion, may consist of cycling between salt fog and dry conditions. More sophisticated automotive methods may ask for multi-step cycles that incorporate humidity, dry air or condensation, along with salt spray and dry-off.

Within one chamber,users can cycle easily through a series of the most significant corrosion environments. Even extremely complex test cycles can easily be programmed with the controller. Biuged CCT&CRH Cabinets can perform salt spray, Prohesion, and 100% humidity for most cyclic automotive tests.

The Cyclic Corrosion Test Cabinets developed and produced by Biuged sets and controls various parameters through the touch screen, and combines multiple tests such as salt spray corrosion, humidity (high temperature and high humidity, low temperature and low humidity), air drying (hot drying and air drying) to simulate a variety of cyclic corrosion tests. Of course, special cyclic corrosion test can also be simulated through the combination of other accessories. The instrument can also conduct neutral salt spray test (NSS), acetic acid salt spray test (AASS), copper accelerated acetic acid salt spray test (CASS), water spray test, damp heat test, drying test and standard atmospheric environment test separately.

Standards

GB/T 1771-2007《Paints and varnishes - Determination of resistance to neutral salt spray(fog)》

GB/T 31588.1-2015/ISO11997-1:2005《Paints and varnishes—Determination of resistance to cyclic corrosion conditions—Part 1: Wet(salt fog)/dry/humidity》

GB/T 2423.17-2008 《Envrionmental testing for electric and electronic products - Part 2: Test method - Test Ka: Salt mist》

GB/T 2423.18-2000《Inspection methods for environmental testing equipments for electric and electronic products—Part 2: Test methods—Test Kb:Salt mist, cyclic(sodium chloride solution)》

GB/T 2423.3-2006/IEC6008-2-78-2001 《Inspection methods for environmental testing equipments for electric and electronic products—Part 2:Testing method—Test Cab:Damp heat,steady state》

GB/T 5170.8-2008《Inspection methods for environmental testing equipments for electric and electronic products - Salt mist testing equipments》

GB/T 10125-1997《Corrosion tests in artificial atmospheres--Salt spray tests》

GB/T 10586-2006 《Specifications for damp heat testing chambers》

GB/T 10587-2006《 Specifications for salt mist testing chambers》

GB/T 10593.2-2012 《Method of the measuring environmental parameters for electric and electronic products - Part 2:Salt mist》

GB/T 12000-2003《Determination of the effects of exposure to damp heat,water spray and salt mist for plastics》

GB/T 20853-2007/ISO 16701:2003 《Corrosion of metals and alloys - corrosion in artificial atmosphere - accelerated corrosion test involving exposure under controlled conditions of humidity cycling and intermittent spraying of a salt solution》

GB/T 20854-2007/ISO14993:2001《Corrosion of metals and alloys - accelerated testing involving cyclic exposure to salt mist, “dry“ and “wet“ condition》

GB/T 24195-2009/ISO16151:2005 《Corrosion of metals and alloys - Accelerated cyclic tests with exposure to acidified salt spray, “dry” and “wet” conditions》

Features

1. Cabinet Structure and Main Parts

◆ The inner working room is made of 1mm pure titanium panels with high corrosion resistance, cabinet body is made of 1.2mm stainless steel with paint

◆ The roof of cabinet cover is designed as 110°angle, which can prevent effectively condensation water from dropping on sample to interfere test results. There is a viewing windows(size is 400mm×280mm)made of transparent tempered glass on the cover.

◆ The cabinet cover is lifted or lowered by cylinder, and speed can be adjusted by air pressure, easy to operate.

◆ The whole cabinet is sealed with high-temperature and corrosion-resistance silicone strips to ensure corrosive gases in the working room do not leak

◆ Specimen Supports:The upper specimen supports are made of corrosion-resistant insulating resin material in a U-shaped groove. Each groove is designed with evenly distributed clasps on both sides to ensure specimen is located at a standard angle(20°±5° from the vertical surface);

The lower specimen supports are a sturdy, removable mesh platform designed for putting workpieces, irregular specimen, or large specimen. The mesh surface prevents the accumulation of salt solution after spraying and facilitates air circulation inside the cabinet. The mesh is made of reinforced fiberglass, capable of bearing a load of ≥600kg/m2(place all samples uniformly).The platform is placed above the heating layer at the bottom of the cabinet, approximately 150mm above the inner cabinet bottom.

◆ The electrical control section and the working room form an integral left-right structure: the working room is on the left, and the electrical section for drying and humidity control is on the right. The water-electric separation structure effectively prevents water/vapor from entering the electrical control section to damage components, safe and reliable.

◆ The cabinet bottom is frame structure which is made of weld stainless steel square tubes, and is equipped with movable Fulham cup feet for moving and locating cabinet easily and quickly.

◆ The back of cabinet is equipped with a drain hole for working room, a drain hole for saturation bucket, a drain hole for fog, a hole for testing, and a hole for importing salt solution automatically.

2. Spraying System

◆ The Supply System for Spraying Solution:The prepared solution is stored in a water tank(external type, 300L). Solution is sucked from the tank by a peristaltic pump and supplied to the nozzles, each nozzle can control separately spraying solution quantity. This design helps to avoid salt crystallizing on the nozzle caused by tradition siphon spraying method.

◆ Spray Fog Quantity Adjustment System:Proprietary patented technology is used for adjusting precisely spray fog quantity.

① Control precisely the quantity of spray solution by peristaltic pump, with a high-precision stepper motor driving the pump. Operator can adjust the supply quantity of spray solution based on his own requirements, enabling constant control of spray fog quantity and saving water.

② Precise control of nozzle spray pressure is achieved through secondary pressure adjustment, ensuring precise atomization and uniform settling of the spray solution in the working room

③ A spray fog quantity adjustment baffle is installed above the nozzles to control the spray fog quantity by adjusting its opening.

◆ Nozzles:Developed using proprietary patented technology, anti-clogging nozzles are made of pure titanium corrosion-resistant material, which can control spray fog quantity and spray angle.

◆ Monitor Spray Fog Quantity:On the left and right sides of the working room, 2 Φ100mm collection funnels are installed at a distance of 170mm from the tank wall and at approximately one-third of the height from the tank bottom. The funnels are connected to the exterior of the tank via hoses, and a 50 ml graduated cylinder is mounted on the exterior wall to monitor the spray fog quantity.

◆ Spraying Fog and Defogging:Spray fog and defogging(using compressed air to fill the working room and then expel the fog quickly)are done by manual or a setting program automatically

◆ Air-saturator Tower:Also known as an air filtered heating pressure tank, made of SUS 304# stainless steel, is used to ensure that the compressed saturated air used for spraying is pure and at a constant temperature. The tower is equipped with a water level control device, heating device, and the temperature control system, with a ring of fine air outlet holes evenly distributed at the bottom. The tower is connected to an oil-water separator and an air source pressure regulating valve of the compressed air source. After the compressed air is adjusted to the required pressure, it enters the air-saturator tower, then enters the water in the tower through the small holes at the bottom, and finally overflows in a bubble-like manner to supply the nozzles from the top of the air-saturator tower. There are water level probes near the bottom and top of the air-saturator tower to achieve automatic water supply and maintain the water level with a specified range. Additionally, the air-saturator tower has water level monitoring and limit alarm funcitions.

3. Control System of Temperature/Humidity

◆ Heating System

① Heating in salt spray cycle:Titanium tubes armored heating devices are installed on both sides of the bottom of the cabinet inner, using heat radiation heating and P.I.D control to achieve long and stable working temperature.

② Heating in humidity cycle:Using titanium tubes armored fin heaters, with strong air circulation from circulating fans, P.I.D control of heating to achieve temperature balance.

③ Heating to air-saturator tower:Using titanium tubes armored heating tubes, heated by heating water. Compressed air enters the hot water and overflow in the form of bubbles. P.I.D control of heating to achieve constant temperature and pure spray gas.

◆ Humidification/Dehumidification System:Use external boiler to humidify, humidification tubes are pure titanium tubes armored heating tubes, P.I.D output control SSR action control of heating output. Use compressor to dehumidify. Use A-grade precise PT 100 platinum resistance sensors for dry and wet bulb comparison to measure humidity.

◆ Cooling System: The system uses low-temperature compressors imported from Europe with an environmentally friendly refrigerant R404a. The system utilizes cold balance technology, saving 30% of electricity and effectively reducing running cost. All system pipelines are subjected to a 22kg leak test with air pressure. All refrigeration system operations are fully controlled by a microcomputer and cooling systems are completely independent. Additionally, the system is equipped with high and low-pressure protection devices that monitor the refrigerant pressure during operation. If the refrigerant pressure exceeds the system’s limit or falls below the set minimum pressure, an alarm is immediately triggered, and the power is cut off until the fault is resolved. The compressor comes with a PTC temperature sensor for overheat protection. The bottom of the compressor is also equipped with a water tray to collect condensate produced by frosting.

◆ Air Conditioning System: The heat-resistant long-shaft motor circulating fan can forcibly circulate air. Behind the cabinet, there is a temperature conditioning chamber installed. Inside the conditioning chamber, there are circulating air ducts, evaporators, humidifying steam outlets, and finned heating pipes. At the top, there is a louvered air outlet, and at the bottom, a return air inlet is installed. The circulating air blows out from the top louvered window, passes through the test space, and then circulates back from the bottom.

4. Operation System

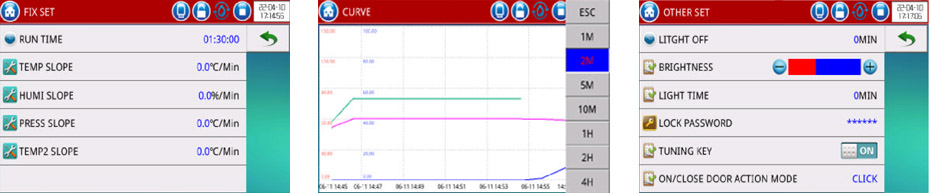

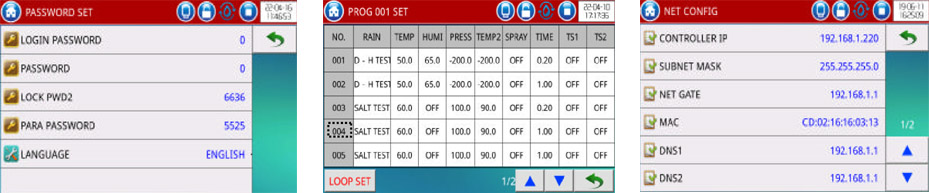

◆ Programmable Controller(Touch Screen Operation):7 inch true-color, 800×480 dot matrix LCD display, freely switchable between Chinese, English and Russian languages. It supports functions such as spraying fog at constant temperature, spray salt solution, drying at high temperature, constant temperature and humidity, alternating temperature and humidity, salt spray + temperature & humidity cycle, etc. The running modes can be done by program, set value, or timed start and stop.

◆ Programming Function:Spray cycle and spray time can be arbitrarily set, the maximum test time for continuous spray is 9,999 hours, the maximum interval spray time is 99 hours and 59 minutes, and the maximum time of stopping spray is also 99 hours and 59 minutes; Up to 120 groups of programs can be edited, each program can consist of 1 to 99 segments; it has a memory capacity of 1,200 segments and can repeat commands(each command can be executed up to 999 times); program linking can be set between programs; program time can be set from 1 minute to 999 hours per segment.

◆ Data Recording Method: With battery-protected RAM, lasting 8-10 years, it can save the set values of the cabinet, sampling values, and the time of sampling; curve recording period can be set from 30 to 180 seconds, maximum memory time stores continuous storage of historical curves for up to 90 days, historical data(with a sampling time of 1 minute); data can be saved for over 10 years when not continuously used.

◆ Communication Function:Comes with standard RS-232, RJ45 Ethernet interface, and USB interface. Can be connected to Ethernet via professional software for remote control and assistance. Can collect test data through the network(hot-swappable, can plug in 1G-16G USB drive to download historical curves, historical data, and control system parameters)or control many cabinets at the same time.

◆ Open Software Function:Supports third-party upper-level code to control device start, stop, and data recording functions. The controller provides function codes, and users can edit upper-level software programs for unified monitoring and control.

◆ Intelligent Functions:Intelligent interconnection, intelligent Fuzzy function, ARW start-suppress overrange, intelligent power saving, intelligent prolong device life function, intelligent output of up to 28 types(built-in timer)mode, intelligent user-friendly control, etc.

◆ Power-off Memory Function:Can set the power-off recovery mode to hot-start/cold-start/stop.

◆ Scheduled Startup Function:Can freely set the startup time. After powering on, the cabinet will automatically run when the set time is over.

5. Safety Protection System

◆ Safety Protection System:Protections for the compressor of cooling system when it is overheat, overload, overpressure, and over temperature; the cabinet has automatic pressure balance protection to prevent overheating; Humidification system has protections against dry burning and water shortage in the humidification heating pipe; Heating system has protections against extreme overheating and short circuit in the heating pipe; and short circuit protection, control circuit short circuit and overload protection; Circulating fan overload, short circuit, and reverse protection.

◆ Work Status Display at the tope of the cabinet: Columnar three-color sound and light alarm(using LED beads); Yellow light stays on when waiting to start or operation is complete; Green light stays on during normal operation; Red light stays on and the buzzer sounds intermittently in case of emergency stop or equipment failure alarm.

Main Technical Parameters

Ordering Information → Technical Parameters↓ | BGD 886/T | BGD 887/T | BGD 888/T |

Working room size(W×H×D)(mm) | 1200×800×1000 | 1600×800×1000 | 2000×800×1200 |

Working Room Capacity (no including V shape cover) | 960 L | 1280 L | 1920 L |

Overall Size(W×H×D)(mm) | 2500×1650×1220 | 2900×1650×1220 | 3300×1720×1420 |

Power/Max. Current | 28.6KW/31A | 28.6KW/31A | 30.6KW/35A |

Power Supply | AC 380V 3 phase 31A | AC 380V 3 phase 31A | AC 380V 3 phase 35A |

Temperature Range | 20℃~70℃(Continuously adjustable) | ||

Temperature Uniformity | ≤ 2℃(When RH ≥ 75%); ≤ 3℃(When RH<75%) | ||

Temperature Stability | ± 0.5℃ | ||

Temperature Rise and Fall Rate | 15℃ → 70℃≧3℃/min (no-load conditions during whole process average) 70℃ → 15℃≧1.2℃/min (no-load conditions during whole process average) | ||

Humidity Range | 20%~98% (Adjustable in P136 range) | ||

Humidity Uniformity | ≤ 2%RH~3%RH(When RH ≥ 75%); ± 5% RH(When RH<75%) | ||

Humidity Stability | ± 2% RH | ||

Salt Fog Precipitation | 1ml~2ml/ 80cm2.h(Adjustable) | ||

Salt Fog Precipitation Uniformity | ±0.5ml/80cm2.h (Collect 16 hours or more) | ||

Spray Method | Continuous or Cyclical | ||

Required Work Environment | Tem: 5~30℃; RH: 45%~85%RH; Barometric Pressure: 86kPa~106kPa | ||

Required Air Supply | Air consumption: 4m3/h, Pressured air without water and oil which has been dried and filtered, pressure is (0.4~0.8)Mpa. | ||

Required Water Supply | It meets the secondary water standard specified in ISO 3696 water specification and test method standard for analytical laboratory. The water supply pressure is within the range of 0.1MPa ~ 0.4MPa. The instrument reserves 1/4 "internal teeth for water supply interface. Note:Distilled water or deionized water is required for preparing spray solution, | ||

Exhaust and drainage | The exhaust pipe of the instrument shall be extended to the outdoor designated position, and shall be led out of the room through opening in the wall near the instrument installation. The exhaust pipe shall not be kept unblocked without water. The exhaust pipe diameter shall be Ф 50mm; The instrument drainage pipeline shall be extended to the outside, and the drainage pipeline shall be unblocked. The drainage outlet shall be lower than the instrument drainage outlet, and the drainage pipe diameter shall be Ф 1/2". | ||

Note:Temperature uniformity and stability datas are tested under 25℃ environment temperature, RH ≤ 85%and no any samples.

Biuged Precise Instruments (Guangzhou) Co.,Ltd

Add:NO.15, Fuzhong Rd., Zhongxin Town,

Zengcheng District, Guangzhou.China

Tel:+86-20-32955999;+86-20-32955820

Fax:+86-20-32955819

E-mail:jack@biuged.com

Website: http://www.biuged.com

Biuged Instruments Co.,Ltd.

Add:RM.310, NO.1, Sicheng Rd.,

Tianhe District, Guangzhou.China

Tel:+86-20-82169666

Fax:+86-20-32955818

E-mail:jack@biuged.com

Biuged Precise Instruments (Shanghai) Co.,Ltd

Add:Room 906, 9th Floor, Zhongcai Industrial Park, No.1111

Zhu Feng Road, Qingpu District, Shanghai, China

Tel:+86-21-59240298

Fax:+86-21-59249719

E-mail:xjx@biuged.com

Biuged Laboratory Instruments (Guangzhou) Co., Ltd. Guangdong ICP record number:11044672

.png)